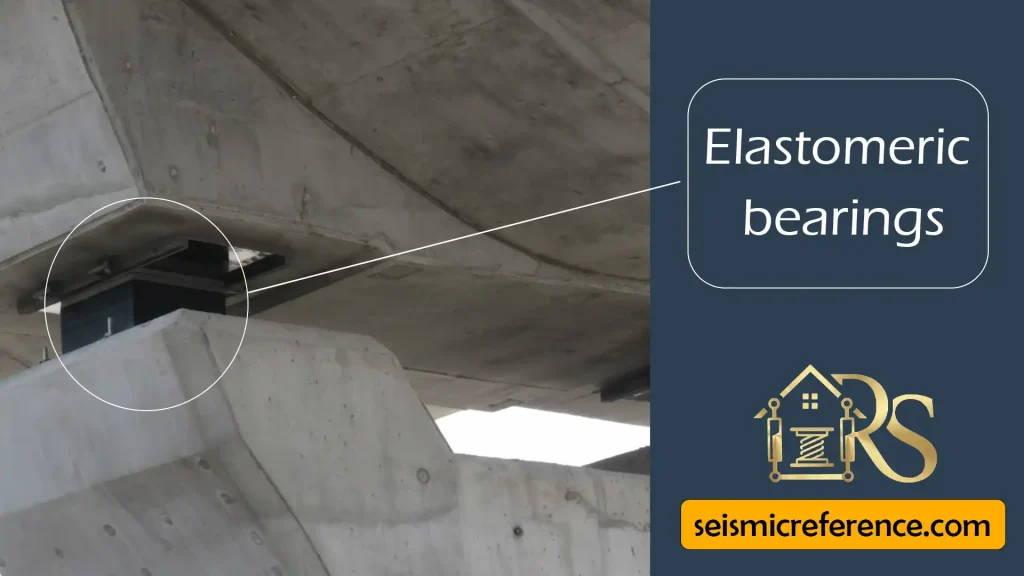

Elastomeric bearings serve as critical components in modern infrastructure, enabling structures like bridges and buildings to withstand movements from thermal changes, seismic activity, and loads while maintaining stability.

Key Points:

- Research suggests elastomeric bearings enhance structural durability by absorbing vibrations and allowing flexibility, reducing the risk of cracks in bridges and high-rises.

- It seems likely that materials like natural rubber or neoprene are chosen based on environmental conditions, with natural rubber favored for cold climates and neoprene for ozone-prone areas.

- The evidence leans toward laminated designs for high-load scenarios, as they incorporate steel reinforcements to boost compressive strength without limiting shear flexibility, though proper installation is essential to avoid failures.

Understanding Elastomeric Bearings

These devices provide a flexible link between structural elements, transmitting loads while permitting movements.

Benefits in Construction

They offer low maintenance and cost savings, making them a practical choice for long-term projects.

Common Challenges

Issues like misalignment can arise, but regular inspections help mitigate them.

Elastomeric bearings have become essential in the realm of structural engineering, offering a unique combination of strength and adaptability to protect infrastructure from various stresses. Positioned as interfaces between superstructures and foundations, elastomeric bearings facilitate the transfer of vertical loads while accommodating horizontal shifts, rotations, and vibrations caused by thermal expansion, seismic events, or dynamic forces. This capability helps prevent structural damage, such as fractures in concrete or steel, thereby prolonging the service life of bridges, buildings, and other constructions.

What Are Elastomeric Bearings?

Elastomeric bearings are specialized supports designed to connect and cushion structural parts.

Definition and Core Functionality

At their essence, elastomeric bearings consist of rubber-like pads that bear weight and allow motion, easing stresses from environmental factors.

Historical Development and Engineering Shift

Originating in the late 19th century with natural rubber applications in railways, elastomeric bearings evolved in the 1950s to laminated forms, shifting from rigid mechanics to flexible systems that now dominate 90% of bridge supports.

Material Science in Elastomeric Bearings

The performance of elastomeric bearings depends on their polymer makeup, adhering to standards like AASHTO M 251 for virgin materials.

Natural Rubber vs. Neoprene Properties

Natural rubber provides excellent cold-weather resilience down to -40°C, while neoprene excels in resisting ozone and chemicals in harsh environments.

| Property | Natural Rubber | Neoprene |

|---|---|---|

| Temperature Range | -40°C to +60°C | -25°C to +60°C |

| Ozone Resistance | Moderate | High |

| Tensile Strength | 2250 psi min | 2250 psi min |

Compounding for Durability

Mixing includes additives like carbon black for strength and antioxidants to combat UV degradation, ensuring long-term reliability.

Mechanics of Laminated Elastomeric Bearings

Laminated elastomeric bearings improve on plain pads by addressing bulging under compression through internal reinforcements.

Steel Shims and Shape Factor Role

Steel shims, encased in elastomer, restrict lateral expansion, with the shape factor determining overall stiffness.

| Shape Factor | Application | Load Type |

|---|---|---|

| <6 | Building pads | Low loads |

| 6-12 | Bridge supports | High loads |

Shear and Rotation Handling

Shear deformation enables horizontal movement, with elastomer thickness designed to double the expected translation for fatigue resistance.

Manufacturing Processes for Elastomeric Bearings

Production demands precision to avoid defects like delamination in elastomeric bearings.

From Mixing to Vulcanization

Raw materials are extruded into sheets, shims primed for bonding, and the assembly vulcanized under heat to form cross-links.

Quality Testing Standards

Tests include 150% proof loading and shear modulus verification to meet ASTM criteria.

Classifications of Elastomeric Bearings

Elastomeric bearings come in various types to suit specific structural needs.

Plain and Laminated Types

Plain elastomeric bearings (Type F) are cost-effective for light duties; laminated (Types B/C) handle heavier loads with anchors.

Sliding and Seismic Variants

Sliding elastomeric bearings use PTFE for extended displacements; seismic ones like LRB dissipate energy via lead cores.

| Category | Construction | Advantage | Use |

|---|---|---|---|

| Plain | Elastomer only | Low cost | Buildings |

| Laminated | Rubber + shims | High load | Bridges |

| Sliding | Rubber + PTFE | Large movement | Viaducts |

| LRB | Rubber + lead | Energy damping | Seismic zones |

Applications of Elastomeric Bearings

Elastomeric bearings are versatile across industries beyond basic infrastructure.

In Bridges and Buildings

They support girders in bridges against wind and traffic, isolating vibrations in buildings for occupant comfort.

Offshore and Industrial Settings

In FPSOs, elastomeric bearings buffer wave impacts; in factories, they dampen machinery noise.

Seismic Protection Roles

As isolators, elastomeric bearings shift structural frequencies to reduce earthquake damage.

Benefits of Elastomeric Bearings

Elastomeric bearings provide multiple advantages in design and operation.

Durability and Cost Efficiency

Resistant to weathering, they last decades with minimal upkeep, lowering overall project expenses.

Vibration and Noise Control

By absorbing shocks, elastomeric bearings enhance environmental quality in urban areas.

Installation and Maintenance for Elastomeric Bearings

Proper handling ensures optimal function of elastomeric bearings.

Step-by-Step Installation

Surfaces must be level; elastomeric bearings are positioned and anchored accurately.

Routine Maintenance Tips

Visual checks for cracks or bulging, with replacements every 20-30 years in high-stress uses.

Standards Governing Elastomeric Bearings

International codes ensure safety and performance of elastomeric bearings.

AASHTO and EN Frameworks

AASHTO offers simplified (Method A) and advanced (Method B) designs; EN 1337-3 requires CE marking.

Design Constraints

Limits on compression, rotation, and buckling prevent failures in elastomeric bearings.

Forensic Analysis of Elastomeric Bearings

Understanding failures helps improve elastomeric bearings.

Common Issues Like “Walking”

Low loads or waxes cause migration; flat seating prevents it.

Inspection Protocols

Regular monitoring for ozonolysis or misalignment, using jacking for replacements.

Sustainability in Elastomeric Bearings

Eco-friendly trends are shaping elastomeric bearings.

Carbon Footprint Comparison

Natural rubber emits less CO2e than neoprene, promoting greener choices.

Future Innovations

Recycled materials and FEA modeling predict long-term behavior of elastomeric bearings.

In conclusion, elastomeric bearings represent a cornerstone of resilient engineering, adapting to modern demands while evolving toward sustainability. Their integration in diverse applications underscores their value in safeguarding infrastructure.

| Aspect | Plain | Laminated | Sliding |

|---|---|---|---|

| Capacity | Low-Medium | High | Medium-High |

| Movement | Limited | Moderate | High |

| Use | Buildings | Bridges | Long Spans |

| Cost | Low | Medium | Higher |

This table compares key features of elastomeric bearings types for quick reference.

Elastomeric bearings continue to advance, incorporating smart monitoring and fire-resistant elements for enhanced safety. Their role in reducing environmental impact through sustainable sourcing aligns with global infrastructure goals. Engineers must prioritize site-specific selections to maximize the benefits of elastomeric bearings, ensuring structures endure for generations.